why cottonseed oil production process is significant

Cotton is one of the most important fiber crops in the world, grown in many countries located in the subtropical and tropical regions. Cotton is primary cultivated for its significance in the clothing industry, precisely for lint or fiber. However lint is the major cotton crop’s product but that is rapidly changing after the realization of the many health benefits of cottonseed oils. The point here is that cotton has become an oil-cum-lint producing plant. Even with the discovery that cotton has up to 25% of proteins, researchers have not yet came up with a surefire cottonseed oil production process.

How much do you know about cottonseed oil? Cottonseed is constituent of kernel and hull. Kernel contains protein, oil, carbohydrates and more constituents like minerals, vitamins, sterols, lecithin and so forth. This oil is extracted from the cottonseed kernel and it is referred to as “heart oil”. This is among the edible oils that are highly unsaturated and that necessitates full hydrogenation before it can be used, just as in the case of many other polyunsaturated oils.

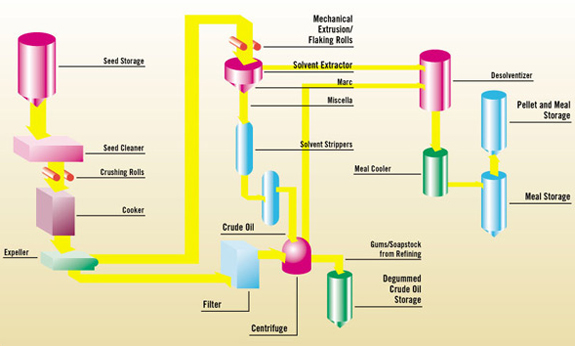

Cottonseed oil production process is relatively new, although the cultivation of cotton runs back many decades. While the first cottonseed oil processing plant emerged as early as in 1793, it is until the twentieth century that it begun being utilized for commercial purposes. The traditional processing of cottonseed oil is significantly different from the scientific processing today. The latter involves a series of activities from linter’s removal, decertification,

hull separation, extraction of solvents to the cottonseed oil refinery. The difference here is that the scientific processing involves almost 100% extraction oil while the cake obtained from tradition processing contains up to 7 percent residual.