The oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment, off-flavor and other impurities. In order to make the oil edible, the impurities must be taken out; such a process is called “Oil Refining”. We are able to supply professional oil refining plant with state of the art edible oil refining technology and related oil refining equipments, we guarantee to the quality of the finished oil and the lowest production cost.

KMEC offers two types of oil refining plants. One is batch oil refining plant, the other is continuous oil refining plant.

Batch Oil Refining Plant: Batch oil refining is used for low capacities from 10TPD to 30 TPD. The advantages are low investment, easy operation and maintenance, less effluent generation.

Continuous Oil Refining Plant: Continuous oil refining plant is used for higher capacities ranging from 30 TPD to 500 TPD and for oils containing high fatty acid (FFA) like Rice Bran Oil etc. The advantages are very superior quality oil, low processing cost.

Workshop of Oil Refining Plant

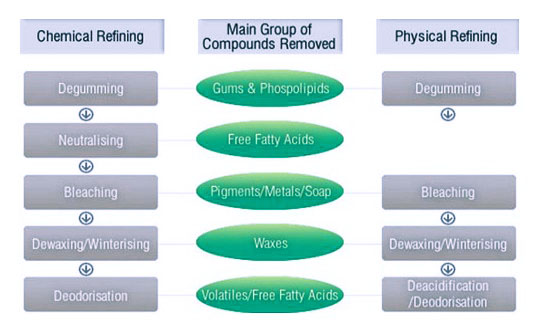

According to different technology of edible oil refining, we classify it into Physical Refining & Chemical Refining. Physical refining means removal of gum in oil during process of degumming in special method and removing FFA in process of deodorizing by steam. Chemical refining means removing FFA in a chemical way (acid-base neutralization). Gum and soap foot produced is separated by centrifuges.

Edible oil refining process always including the following sections: degumming, neutralizing, bleaching, deodorizing and dewaxing.

In the entire edible oil refining process, a lot of refining equipments can also be used, such as neutralizing pot, degumming pot, centrifugal, bleaching tower, vacuum filter, deodorization tower, FFA catcher, crystallizing pot, press filter etc.

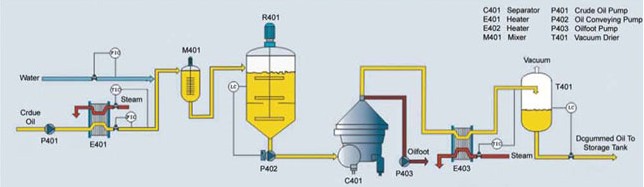

Edible Oil Refining Process – Degumming

Hydration Degumming: Hydration degumming mean adding into some hot water and controlling the corresponding conditions to make the hydrosol agglomerated, deposited and then separate them. The separated gum(after being dried) can be made into lecithin or added into cakes or meals in the extraction workshop. Hydration degumming process can improve oil edibility, storage and do good to downstream neutralization section.

Special Degumming: The technology is specially developed to meet the demands of physical refining for edible / vegetable oil refining. Add small quantity to acid or dilute base to the vegetable oil, strictly control the corresponding conditions to separate out the hydrated gum and un-hydrated gum. Gum level in oil should be controlled to suitable for downstream processing.

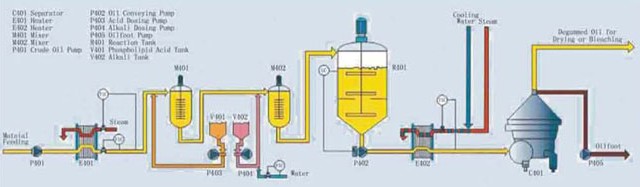

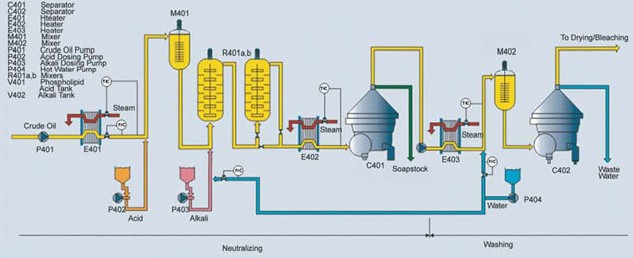

Edible Oil Refining Process – Neutralizing

Since there are many kinds of oilseeds and the oilseeds quality is different from each other, we combine the merits of many technologies and develop the versatile neutralization washing technology. The technology can be used to process oil of various kinds, quality and requirements. Add into alkali, water and acid to remove FFA, crude phospholipids and moisture. As a result, (degummed and neutralized) oil and by-products such as soap foot, crude phospholipids and water are obtained.

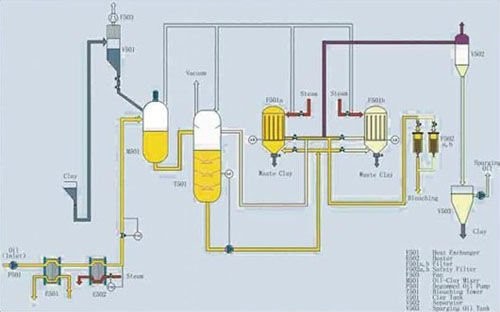

Edible Oil Refining Process – Bleaching

High activity clay is added into oil. Mix and heat mixture of oil and clay to make the small particle of pigment absorbed on the crystal of clay. At last filter the oil. Perfect mechanism, liable performance, well configured equipment-Bleaching Tower and Filters ensures excellent bleaching and separation effect.

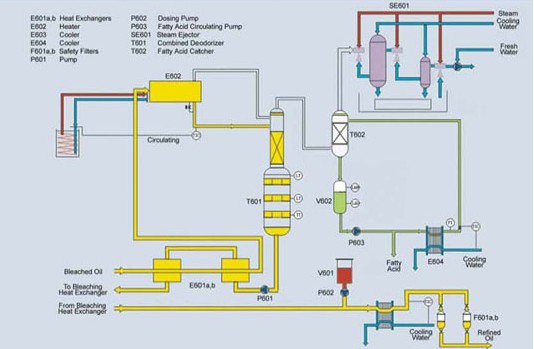

Edible Oil Refining Process – Deodorizing

Combined deodorizing is the latest technology, which improves oil flexibility significantly. Detailed deodorizing process in the entire oil refining plant is: Most heat of bleached oil is recovered by Heat Exchangers. The bleached oil is heated to the process temperature by mineral oil or high pressure steam and then the oil enters into the Combined Deodorizer. The Deodorizer is a combined type: The upper is packing structure, which is used to remove odor components like FFA; the lower is a plate type used for heat bleaching and making product quality more consistent. Oil coming from the Deodorizer is cooled and stored after series of heat exchanger. Volatile like FFA is collected and stored as by-products.

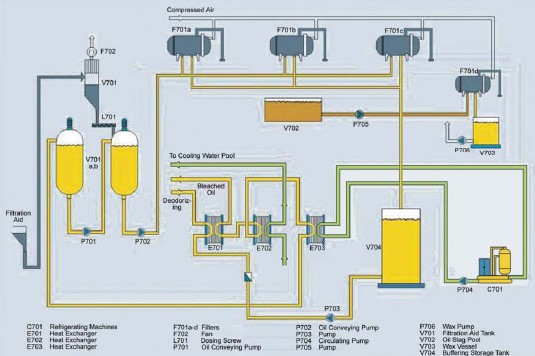

Edible Oil Refining Process – Dewaxing

Dewaxing can improve oil quality, so it plays in important role to the finished edible / vegetable oil quality. At the same time, dewaxing can improve oil transparency and brightness. It is necessary to dewax for some oilseeds such maize oil, rice bran oil, sunflower oil and cotton seed oil. At present, winterizing method is very popular to dewaxing. The crystallizing rate, crystallization temperature, maturing time vary with oil features.

We supply complete set of edible oil refining plant, we offer quality oil mill machinery, We accept enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us to get more info about our products!